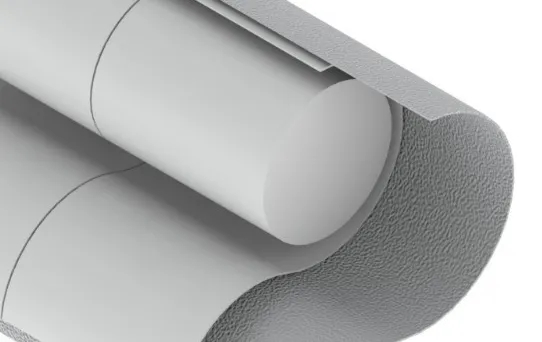

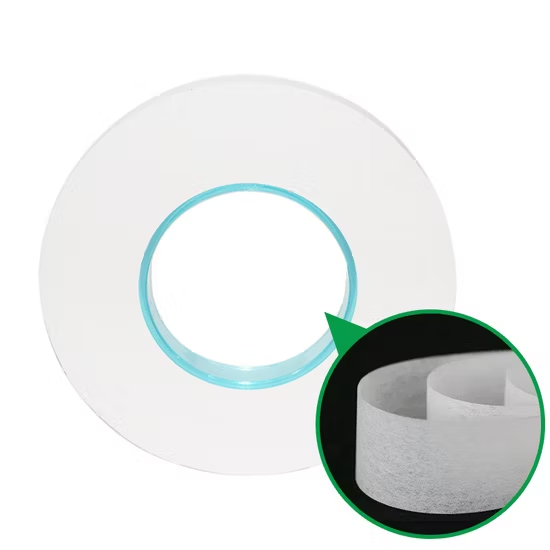

Every plug wrap paper is used as an important part of cigarette filter production. It acts as the outer layer around the filter, housing the filter material, and is a critical aspect of how they function. Indeed, the paper used as the "plug wrap" will have a big influence on how easy it is to draw through and how much the airflow and filtration are estimated, as well as the flavor profile of the end product.

Types of Plug-Wrap Paper

1. Cellulose Acetate Stick Plug Wrap Paper

A very common, very versatile plug-wrap paper that achieves a balance between strength, filtration, and cost-effectiveness.

Features:

- Made from cellulose acetate, a strong yet flexible thermoplastic polymer.

- Has high intrinsic porosity that makes it good for filtration.

- Offers a smooth, even surface for the filter.

- Virtually a standard material in cigarette filter production.

Applications:

- Commonly employed in traditional cigarette filters owing to its combination of strength, filtration, and economical properties.

2. Glassine Plug Wrap Paper

A slick, slimy sheet is used alone or in combination with other materials to enhance filter formation and performance.

Features:

- Made of wood pulp, glazed in a special process.

- Providing smoothness with a low coefficient of friction for easy filter formation.

- Offers excellent grease and moisture resistance.

- It is often combined with other materials to improve the effectiveness of the filter.

Applications:

- Often it is used in conjunction with other materials, such as cellulose acetate, to produce various filters in layers for enhanced filtration.

3. Polypropylene Plug Wrap Paper

A light and porous paper used in most ventilation-style filters today to increase airflow and flavor enhancement while reducing some of the harmful ingredients of the smoke.

Features:

- Constructed from thin polypropylene thermoplastic, which is very light yet strong.

- Highly porous with good ventilation properties.

- Yields high chemical and moisture resistance.

- Easily manufactured and able to be piped into fast-paced manufacturing lines.

Applications:

- Prominently used in the construction of contemporary ventilated filters, intended to diminish the delivery of some of the highly studied harmful cigarette smoke constituents.

4. Viscose Plug Wrap Paper

A high-strength, high-flexibility paper, which can be combined with other materials to make filters with certain performance criteria.

Features:

- Made from wood pulp like cellulose acetate but has a different chemical structure.

- Provides good strength and flexibility while allowing for some filtration.

- They may be mixed with other materials to give effective filter properties.

Application:

- It is often combined with other materials to make combination filters with desired properties.

5. Specialty Plug Wrap Papers

Inventive papers that integrate unique materials and technologies influence precise filtration objectives and respond to changes in consumer needs.

Features:

- Utilizing novel materials and technologies to meet particular filter performance objectives.

- May contain an additive like activated charcoal or other types of filtering agents.

- Can be engineered to decrease the delivery of certain harmful elements in smoke.

Applications:

- Employed in high-level filter designs to meet particular customer needs and legislation demands.

Conclusion

Choosing the plug wrap paper is one of the most important and difficult tasks in cigarette filter production. Material selection affects airflow, filtration, and the smoking experience very much. Manufacturers can evaluate the necessary properties and desired levels and choose the ideal plug-wrap paper from which to produce high-quality, consistent, consumer-pleasing cigarettes.